|

HOLK Bearing Co., Ltd

|

Impact Bars for Conveyor Impact Beds

| Payment Terms: | T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Impact Bars for Conveyor Impact Beds

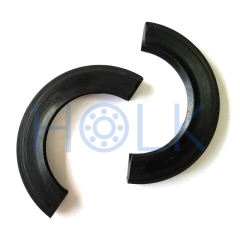

Material: UHMWPE, Rubber, Aluminum

Extremely low coefficient of friction for long wear life

The Impact Bars are used to prevent damage to the conveyor belt at the loading points, to keep the belt stable and to avoid the spillage of the conveyed material.

We manufacture top-notch quality Impact Bars for the conveyor system. Our impact bars have been specifically formulated and engineered to absorb and disperse the force of impact in load zones, preventing premature wear and damage to the conveyor belt.

Proudly to supply high quality impact bars for a big American engineering company for many years.

General Technical Parameters/Specs

Product Name: Impact Bars

Material: UHMW Polyethylene, Rubber Cushion and Aluminum Extrusion Inserts

UPE Color: White, Blue, Black

UPE Tensile Strength: 30 MPa

UPE Elongation at break: 300%

UPE Shore A Hardness: 96-98

UPE Proportion: 0.93-0.94 g/cm3

UPE Friction Coefficient: 0.07

Rubber Color: Black

Rubber Tensile Strength: 19 MPa

Rubber Elongation at break: 400%

Features of our Impact Bars:

Unlike roller sets, Impact Bars fully supports the belt and prevents sagging

Less wear and risk of damage to the conveyor belt

Extremely low coefficient of friction for long wear life

Absorption of the shocks due to the impact of the material falling on the belt conveyor

Easy installation and reduction of maintenance time and costs

Easy conversion from traditional impact systems

Availability for any belt type and width and any inclination angle

The T-bolt fixing system allows an easy and safe installation.

Meets all international and industry standards and requirements.

Drawing of Impact Bars

| Measurements of Standard Impact Bars | |||

| Length A (mm) | Width B (mm) | Height H (mm) | UHMW-PE Thickness H2 (mm) |

| 600 | 100 | 50, 75, 100 | 8, 12.7, 15, 20, 25 |

| 700 | |||

| 750 | |||

| 800 | |||

| 900 | |||

| 1000 | |||

| 1220 | |||

| 1400 | |||

| 1524 | |||

| 1600 | |||

| 1800 | |||

| 2000 | |||

| Non-Standard and Custom-Made Impact Bars are available upon request. | |||