|

HOLK Bearing Co., Ltd

|

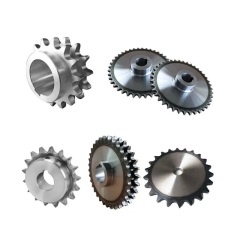

Needle Bearing Idler Sprockets & Ball Bearing Idler Sprockets

| Payment Terms: | T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Ball Bearing Idler Sprockets

Needle Bearing Idler Sprockets

Pilot Bore, Finished Bore, Taper Bore

Steel, Stainless Steel, Plastic

Most of the time, selecting a power transmission component can be very challenging, especially when it is a fundamental part like a sprocket.

A Sprocket, also known as Sprocket-Wheel or Chainwheel is a profiled wheel with teeth that mesh with a chain, track or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passing over it. It is distinguished from a gear in that sprockets are never meshed together directly, and differs from a pulley in that sprockets have teeth and pulleys are smooth except for timing pulleys used with toothed belts.

Sprockets are available in a variety of configurations, which must be matched accurately to a machine's design. Chain Sprockets can be specified either by designation or product type.

Types of Chain Sprockets

Idler Sprockets are a flat hubless sprocket, with a sealed bearing that allows the sprocket to rotate freely. The bearings used in our idler sprockets use a wide inner race to create spacing between components on a shaft. Idlers are normally mounted in a fixed position on a fixed shaft or attached to a tensioner arm.

Construction of Idler Sprockets

Idler Sprocket Teeth - The teeth on our idler sprockets come standardly hardened from 30-teeth and under to ensure elongated durability.

Idler Sprocket Body - The materials used in our idler sprocket bodies are premium carbon steel, stainless steel (SS 304 or SS 316), or Nylon plastics.

Idling Component - This component is typically a ball bearing, needle bearing, bronze, or non-metallic plastic.

Different Types of Idler Sprockets - Ball Bearing Idler Sprockets-Needle Bearing Idler Sprockets-Bronze Bearing Idler Sprockets

HOLK Bearing is a leading manufacturer of a wide range of power transmission products such as Chain Sprockets, Gears, Bearing Housings, Adapter Sleeves, Withdrawal Sleeves, Precision Lock Nuts, and many other bearing accessories.

All HOLK's sprockets are made from top-notch quality steels and can be further adapted for high performance with coatings such as black oxide or zinc plating.

To enhance the hardness and wear resistance of the tooth surface, the tooth surface can be subjected to high frequency quenching and heat treatment, thereby increasing the life of the chain sprockets and gears.

HOLK's chain drive transmission systems grant high performances on a wide array of industrial applications. Their resistance to wear and fatigue is way above the standard requirements according to relevant ISO regulation. Thanks to our top-notch production capacity, we can offer many different series and also customised power transmission products.

Aside from standard products, we can also produce special customised Chain Sprockets, Gears, Gear Racks, and many other industrial products according to customers' drawings and samples.

Features & Benefits

Manufactured according to DIN8178 and ISO/R606 standards

Available in plate, single hub and double hub configurations

Made from high-grade steel and carbon steel

Stainless steel plate wheels, cast iron plate wheels, and ASA standard plate wheels are available on request

Optional taper bushes simplify installation and removal

Surface treatment such as black oxide and zinc plating are available upon request